Product Description

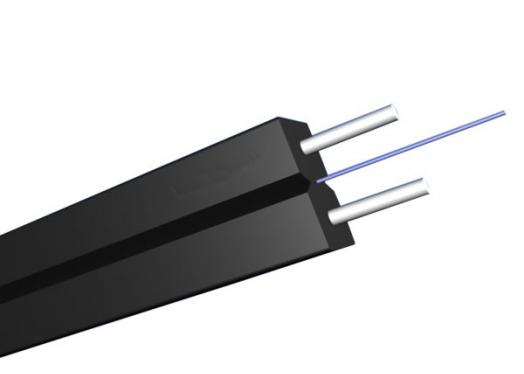

Tight Buffer Optical Fiber Cable 2mmx3mm 2FO Without Aerial Steel Wire

|

PRODUCT |

FTTH CABLE |

|

MODEL |

FTTH2x5 2FO |

|

FIBER OPTICS |

G657A1 |

|

MATERIAL OF CLADDING |

LSZH |

|

AERIAL STEEL |

7x Ø 0.33 mm |

|

FIBER PROTECT STEEL |

2x Ø 0.4 mm |

|

NUMBER OF CORE |

2 |

|

SIZE OF CABLE |

2.0×3.0 ± 0,1(mm) |

|

DIMENSION OF BOBBIN |

300x300x280 |

|

WEIGH |

20KGS |

|

Technical parameters |

Unit |

Standard specifications |

|

| Specifications for FTTH Cable | |||

| Overall structure for FTTH Cable | FTTH Cable has a rectangular cross section structure | ||

| Colored optical fiber code | 1FO/2FO/4FO | ||

| Cladding | Material | LSZH plastic | |

| Thickness | Average 0,8mm ± 0,1mm | ||

| Cladding is made of high quality LSZH, composed of carbon (light yellow color for lines running inside the home), UV – resistant, contains suitable antioxidant, does not develop mildew, electrical insulation. | |||

| Cladding protects the core from mechanical and environmental forces during storage, assembly and operation (water, heat, chemicals, insect bites,…) | |||

| Subscriber line coating is smooth, concentric, without connecting points, without cracks, without holes, of even quality ( not rough, does not have bubbles, not divided, no bumps, no holes, no lumps), does not contain metal; flexible, firm, easy to open; optical fiber does not stick to coating when opening; sleeve thickness is even along cable length. | |||

| Separating the hanging wire from the cable does not change the structure of cable nor affect the quality of optical fiber in it | |||

| Additional reinforcing component (Bearing wire )

|

Material | zinc – coated single steel wire | |

| Diameter | ³ Ø 0,4 mm | ||

| Number of wire | 2 zinc – coated steel wire placed on both sides to protect optical fiber | ||

| Hanging wire | Material | zinc – coated steel wire : steel wire tape (7 wires x ≥ Ø 0,33mm) | |

| Sleeve | LSZH plastic

Average thickness 0,5mm ± 0,1mm |

||

Optical and geometrical characteristics for single – mode optical fiber according to ITU – T G.657.A1

|

Technical parameters |

Unit |

Specifications |

Measurement method |

|

| Attenuation coefficient |

dB/km |

At 1550nm |

≤0.25 |

IEC 60793-1-40 |

| At 1490nm |

≤0.25 |

|||

| At 1310nm |

≤0.36 |

|||

| Chromatic dispersion index |

ps/(nm.km) |

≤3.5 at 1285nm to 1330nm,

≤18 at 1550nm |

IEC 60793-1-42 |

|

| PMD coefficient |

Ps/km1/2 |

≤ 0.2 |

IEC 60793-1-42 |

|

| Chromatic dispersion coefficient |

ps/(nm2.km) |

£ 0.092 |

IEC 60793-1-40 |

|

| Wavelength |

Nm |

lcc≤1260 |

IEC 60793-1-44 |

|

| Bending loss (d=15mm x 10 rounds) |

Db |

£ 0.25dB at 1550nm |

IEC 60793-1-47 |

|

| Bending loss (d=10mm x 1 round) |

dB |

£ 0.75dB at 1550nm |

IEC 60793-1-47 |

|

| Mode field diameter |

µm |

8.6±0.4 at 1310nm |

IEC 60793-1-45 |

|

| Mode field eccentricity |

µm |

£ 0.5 |

IEC 60793-1-20 |

|

| Diameter of reflection Coating |

µm |

125 ± 0.7 |

IEC 60793-1-20 |

|

| Non-circularity of reflection coating |

% |

£ 1.0 |

IEC 60793-1-20 |

|

| Cladding diameter |

µm |

245mm ± 5mm |

IEC 60793-1-21 |

|

| Attenuation surge point |

dB |

0.1 |

IEC 60793-1-40 |

|

| Strain of fiber |

Gpa |

≥0.69 |

IEC 60793-1-30 |

|

| Primary cladding is made of UV – resistant material (Acrylate), minimizing environmental effects | ||||